Auxiliary Equipment

-

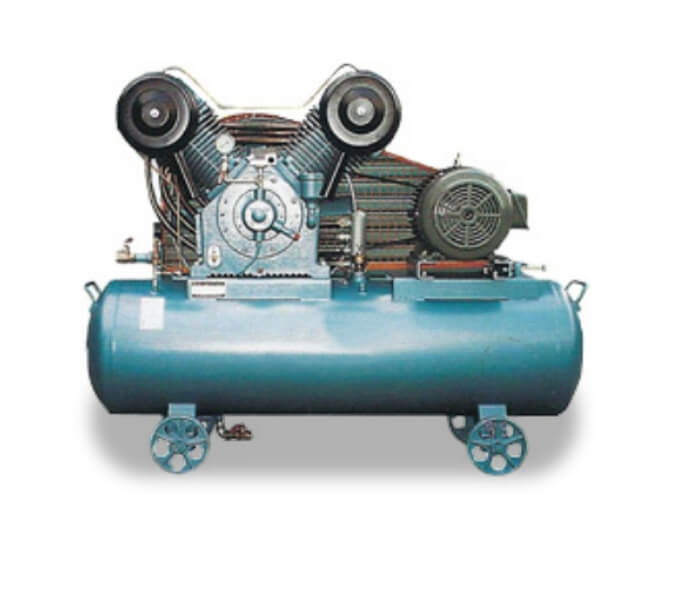

Air Compressor

Air compressor supplies air source for blow molding use. Air compressor supplies air source for blow molding use.

- The hydraulic-type air compressor is widely used in the general industry. Easy to use, simple maintenance.

- An oil-free air compressor contains no oil, and it is suitable for the precision industry, medical industry, food industry, etc.

-

Chiller

Chiller is used for mold cooling and lower oil temperature to increase production efficiency.

A. Water chiller:

- It can be used indoors or in poorly ventilated places.

- In addition to a better cooling performance than an air chiller, the price is also more affordable.

B. Air chiller:

- The air-cooled model does not need to be equipped with a cooling tower, and it can be applied to areas where water quality is poor and frigid in countries.

- Piping is simple which only needs two pipes installation and a water supply pipe.

- If the heat dissipation is poor, simply clean the filter with an air gun will solve the problem.

-

Cooling Tower

The cooling tower is used for heat rejection by circulating in a water recycling system. It uses water as the refrigerant for cooling the heat exchange equipment.

-

Auto Loader

Automatically feed plastic materials.

- Labor-saving. Alarm notification for the shortage of materials.

- It can be equipped with a proportional valve device.

-

Proportional Valve

This proportional valve is connecting with the auto-loader to load virgin and regrind materials by different percentage

- Simple installation and easy operation.

- Able to load new and regrind materials by different timing setup.

- To ensure the materials mixing more evenly, the valve is equipped with 1~4 levels working function selection.

-

Crusher

It is capable of crushing various plastic materials such as PE, PP, PVC, etc. By using the recycled material, the production cost is reduced.

- Use imported steel for the blade to ensure quality and durability.

- Unique blade design to improve cutting effect and lower noise.

- The structure is simple and easy to maintain.

- Compact in size and high mobility.

-

Mixer

Use for blending new and regrind materials. Also, it can be used for blending the colors of various plastic materials.

- There is a protective device on the hopper lid. Once the hopper lid is opened by misoperation, the machine will stop to avoid danger.

-

Conveyor

Conveyors are widely used in various industries to achieve automatics production purposes.

- Customized design to meet various needs.

- The running speed can be adjusted within a range.

- The conveyor belt can be adjusted vertically and inclined angle.

-

Leak Detector

It is used for leak detection of various bottle shapes.

- According to the different sizes of the bottle, the height of the device is adjustable within a range.

- The number of leak detection heads can be increased to multiple according to the production demand.

-

Labeling Machine

This equipment is suitable for flat, square, or irregular container labeling.

There is an option of one side or two sides labeling.

-

In-Mold Labeling

Different from the traditional way of labeling, in-mold labeling is to insert a label into the blow mold by a robotic arm. When the bottle is blown, the label and the container are forming together. This technique benefits on the label not easy to fall off, wash-resistant, washable, anti-counterfeiting, etc. It is widely used in various packaging: food containers, cleaning supplies, oil bottles... etc.

There is an option of one side or two sides labeling.

-

Neck Trimmer

A Neck trimmer is frequently used for wide-mouth containers. Some food packaging will reserve the mouth of the bottle until the filling process in order to keep the bottle clean.

- The height of the machine is adjustable for multi containers.

- Can be online or offline with a blow molding machine.

- Blade by high-quality steel to guarantee durability.

-

Hopper Dryer

Plastics containing water vapor tend to produce bubbles on the surface of the container during blow molding. To ensure the quality of the final product, it's highly recommended to have a hopper dryer for some plastic materials such as PS, PP, PVC, etc as they easily absorb moisture. The maximum drying temperature can reach 160°C. In order to meet different production needs, there are a variety of accessories such as hot air recycler, magnetic base...etc as options.

- Adopt P.I.D temperature control and LCD display

- Overheating protection system to ensure safe and stable operation.

-

Mold Temperature Controller

It is applied to mold heating and maintains mold temperature. When the temperature of the mold is unstable, it will affect the production quality. The life of the mold is increasing when the mold is used at a constant temperature.

- P.I.D. Microcomputer system enables accurate mold temperature control.

- Built-in several protection devices such as abnormal temperature, lack of water or oil, non-fuse switch, and overload alarm system loops to ensure safety.