Q&A

Turnkey Project Planning

- Turnkey project for mineral water bottling line [PET]

- Turnkey project for carbonated drink bottling line [PET]

- Turnkey project for beverage bottling line [PET, HDPE, PP]

- Turnkey project for food packaging including preserves, candy, cookies, powder, granules, etc. [PET, HDPE, PP]

- Turnkey project for daily products including milk, soy milk, vinegar, edible oils, etc. [PET, HDPE, PP]

- Turnkey project for home use products including lubricants, detergents, shampoo, body lotion, etc. [PET, HDPE, PP]

- Turnkey project for cosmetics and pharmaceutical bottling line [PET, HDPE, PP]

(1) A pre-form is injection molded.

(2) The pre-form is blow molded into the shape of a bottle.

The injection machine first produces the pre-form. The pre-form must then cool and solidify, at which point it is discharged from the mold. The cooled pre-form is then placed in the stretch blow mold machine to complete the bottle.

In this method the pre-form material is PET/ PP.

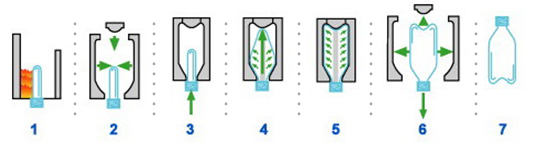

(1) Pre-form heating.

(2) Pre-form is introduced into the mold and closing unit.

(3) Insert the stretching rod.

(4) Stretching and pre-blowing.

(5) Final bottle blowing.

(6) Mold opens.

(7) Finished bottle discharged from the mold.

- Preform Injection Molding Machine

- Preform Injection Mold

- Mold Surface Dehumidifier

- Preform Conveyor

- Resin Dehumidifying System

- Mold Chiller System

- Air Compressor

- Air Dryer

- Precise Filter

- Cooling Tower System

- Stretch Blow Molding Machine

- Blowing Mold

- Mold Chiller System

- Air Compressor

- Air Dryer

- Precise Filter

- Cooling Tower System