6 Functional Categories of Extrusion Blow Molding Applications

1.Petrochemicals & Chemical

Blow molding plays a pivotal role in creating containers for petrochemicals and lubricants. Materials like HDPE and LDPE are commonly utilized in the process. Notable products include plastic fuel tanks, motor oil bottles, petrochemical tanks, jerry cans, lubricants, and glue grease. Employing multiple layers enhances gas barrier properties, extending storage life. Additionally, the use of recycled materials contributes to eco-friendliness and cost-efficiency.

Chia Ming excels in multi-layer techniques and can guide you effectively. Explore our CM-L series co-extrusion blow molding machines for reference or reach out to us for more information.

2.Food Packaging

Food packaging demands versatility, accommodating a range of liquids from thin to thick. Thin liquids like soy sauce, vinegar, cocktail sauce, edible oil, and juices, as well as thicker options like milk, yogurt, and sauces, find ideal containers through blow molding. Certain products, especially oxygen-sensitive ones like mayonnaise or ketchup, require multi-layered packaging to ensure their preservation and quality. Additionally, some items may require specialized layers, such as acid-resistant barriers or UV barriers, to enhance food safety and prolong shelf life.

In this diverse landscape of food packaging needs, co-extrusion blow molding machines, specifically the CM-40P and CMR-45P.6ST models, prove highly effective, particularly for the production of popsicles or frozen bars in a multitude of forms.

3.Household Cleaning Supplies

Blow molding technology also caters to the production of household cleaning supplies. Products like liquid detergent, floor cleaner, glass cleaner, and various other cleaning agents benefit from this process. Chia Ming's CM-65SH2D blow molding machine with deflashing device and parison control is adept at producing specialized products like bellows plungers, ensuring the perfect shape and thickness.

4.Pharmaceutical & Medical Supplies

The pharmaceutical and biomedical industries extensively utilize blow molding for packaging. HDPE jars find applications in packaging medical pills, capsules, supplements, and powders, while LDPE is preferred for liquid products like syrups and nasal sprays. PVC is utilized for oxygen masks, and PP serves as drip bottles. Chia Ming’s CM-40 series pneumatic extrusion blow molding machine is apt for small containers such as drug bottles and cough syrup containers.

5. Personal Care Product

The personal care industry relies heavily on blow molding for packaging solutions. Products like shampoo, hair conditioner, body lotion, and various skincare and grooming items are effectively packaged using PET, PP, and PE materials.

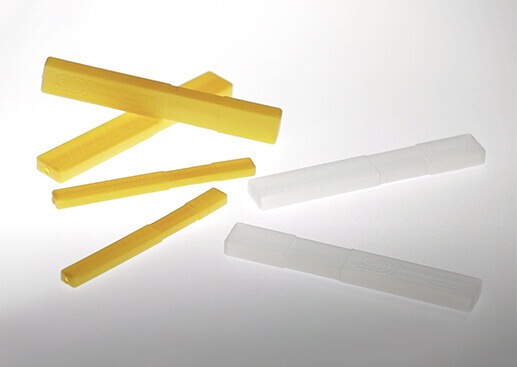

6. Miscellaneous Applications

Aside from the aforementioned categories, blow molding machines excel in creating diverse forms, including toys, bellows, blade cases, roll-on balls, toolboxes, teapots, car parts, tables, road blocks, and more. This technology showcases its versatility in producing a wide array of plastic sports equipment, tree decorations, and everyday items.

Interested in Learning More About Blow Molding Applications?

If you're interested in diving deeper into the world of blow molding applications and understanding how Chia Ming can cater to your specific needs, explore our extrusion blow molding machines or reach out to us for more information.